He knows about itACAe

Sharing of ideas

It was a real pleasure to participate in the event "The PULSATE 2024: Laser Innovations Summit" of 18th and 19th June 2024, by presenting an innovative application of SLM technology and DfAM methodology, participating in a very interesting debate on innovative applications of laser technology, meeting many experts in the sector. ITACAe is one of the beneficiaries of the EU-funded initiative called "PULSATE", a PAN-European Network designed to boost the adoption of laser-based advanced and additive manufacturing (LBAAM) technology.

The funded project "OPTIPOMIX" (OPTImisation of a POlyurethane MIXer), which started the 15th January 2024 and will last four months, aims at the demonstration of the feasibility and the capabilities of the DfAM (Design for Additive Manufacturing) methodology used to define optimized geometrical parts: a polyurethane mixer head and a refrigeration block. The benefits are related to weight reduction, consequently robotic arm dimensioning, and thermal exchange effectiveness.

The activity will be carried out together with experts in the industrial machine production sector (SPM Società Produzione Macchine s.r.l. with Andrea Martinello), of additive manufacturing (T.O.B. ThinkOutsideTheBox by Maurizio Romeo).

https://www.pulsate.eu/insights/18-pulsates-2nd-open-call-for-adopters-meet-the-beneficiaries/

https://ac.epic-photonics.com/pulsate-2024

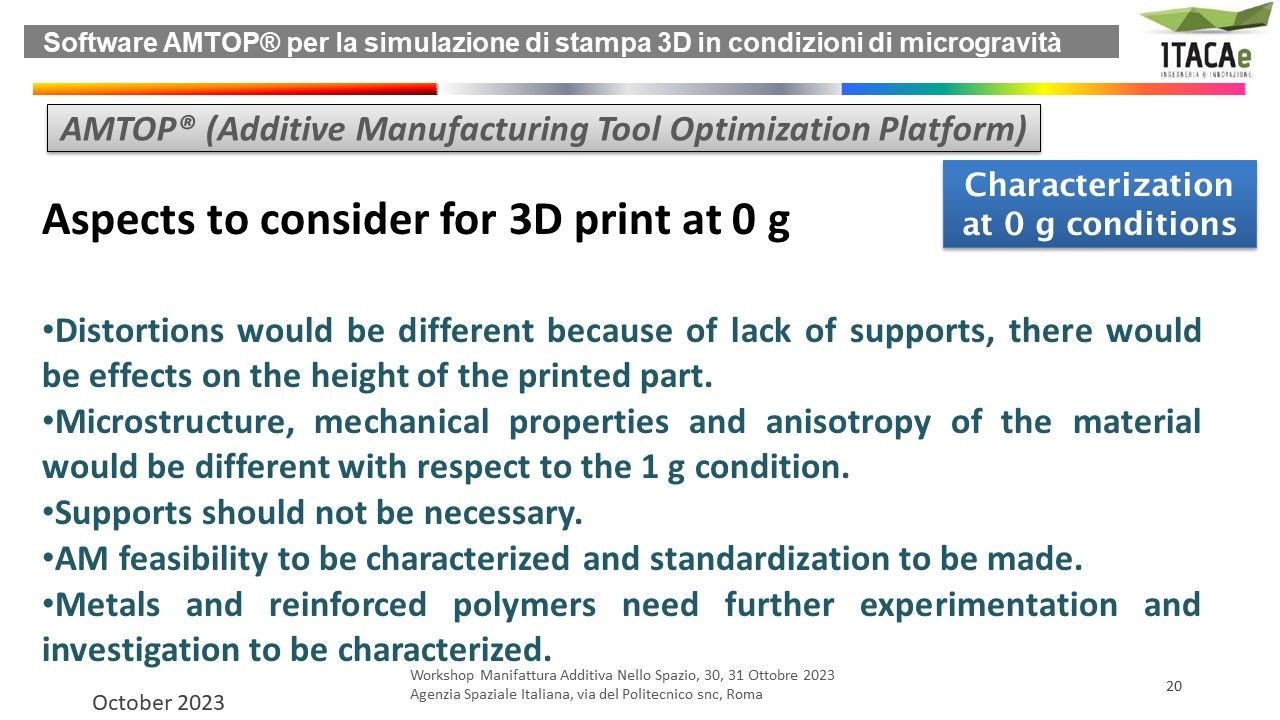

On 30 and 31 October 2023, the "Additive Manufacturing in Space" workshop organized by the Italian Space Agency (ASI) was held in hybrid mode, with the aim of presenting, consolidating and promoting the Italian state of the art. In this occasion the scientific and industrial community could share the results acquired and discuss in view of future space missions.

ITACAe contributed in the section "Additive Manufacturing in Space: open problems and innovative approaches", with a presentation of the implications and advantages of simulation and optimization of the additive manufacturing process in extraterrestrial space, entitled "AMTOP® Software for 3D Printing Simulation in microgravity conditions".

https://www.asi.it/event/workshop-manifattura-additiva-nello-spazio/

“Robotics and additive for manufacturing and beyond” took place on Thursday 12 October, from 9.00 to 17.30, at VOLANDIA (Area Ex Officine Aeronautiche Caproni 1910 – Malpensa), the first conference dedicated to robotics and additive manufacturing, jointly organized by AITA-ITALIAN ASSOCIATION OF ADDITIVE TECHNOLOGIES and SIRI – Italian Association of Industrial Robotics, with the patronage of the UCIMU Foundation, 34.BI-MU, RobotHeart and PiùAdditive.

ITACAe presented the results of an activity carried out together with experts in the industrial machine production sector (SPM Società Produzione Macchine s.r.l.), of additive manufacturing (T.O.B. ThinkOutsideTheBox by Maurizio Romeo). With design for additive manufacturing, a topic that has involved us with passion and conviction since 2015, we combine attention to DFAM technological and methodological innovation with consolidated skills in the design and engineering CAD and CAE of industrial products.

The complete program: https://www.bimu.it/eventi/robotica-e-additivo-per-la-manifattura-e-non-solo/Nuovo paragrafo

Materials, Volume 16, Issue 13 (July-1 2023): a paper was published thanks to a cooperation between University and Manufacturing, Services and Software Industries:

Politecnico di Torino SPEM | Additive Manufacturing Company TEC Eurolab Srl ITACAe

In this paper we demonstrate the importance of FEA to simulate the additivemanufacturing process applied to an artifact defined according to suggestions by ISO/ASTM 52902:2019, manufactured in AlSi10Mg by Selective Laser Melting (SLM) and then analyzed with industrial computed tomography (iCT). The FE model considered some simplifying hypotheses to reduce the computation time and, thus, make it suitable for industrial applications.

The numerical campaign demonstrated the benefits of process simulation to analyse stresses and distortions on small features and proved the absolutely not trivial effects of convection heat exchange and the amount of removed material from the bottom surface of the part due to cutting process.

Another step towards zero-defect, one-shot production of additivemanufacturing through

virtual manufacturing.Nuovo paragrafo